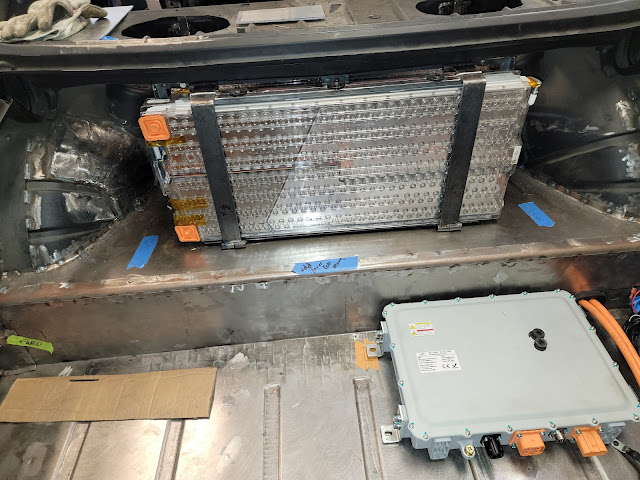

A slicker shifter

Wow. Almost 6 years ago I posted about the shifter mechanism I designed to adapt the stock automatic shifter for EV use. In those 6 years my CAD abilities have improved dramatically and I've upgraded my 3D printer to a Bambu H2D. I was never happy with the feel of the detents of the first version so I set out to improve it. Basically, I used off-the-shelf threaded ball-spring detents and slick UHMW plastic to eliminate the inconsistencies of the offset bearing design from before. The new design is better and described in the video below.