With 10 Tesla Model S batteries up front, the job is only 71% done.

Because the Tesla drive unit needs a minimum of 272 volts to operate, and each

module has up to 28 volts, there would be basically zero range with 10 fully

charged modules. Therefore, I need to add at least 4 more modules to the

car somewhere to get any power or range.

|

|

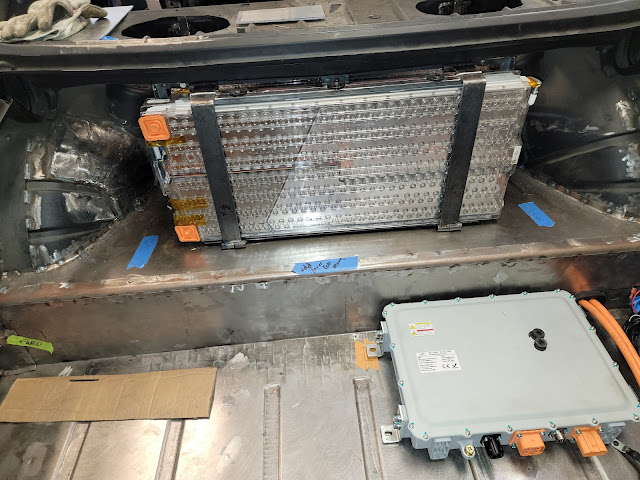

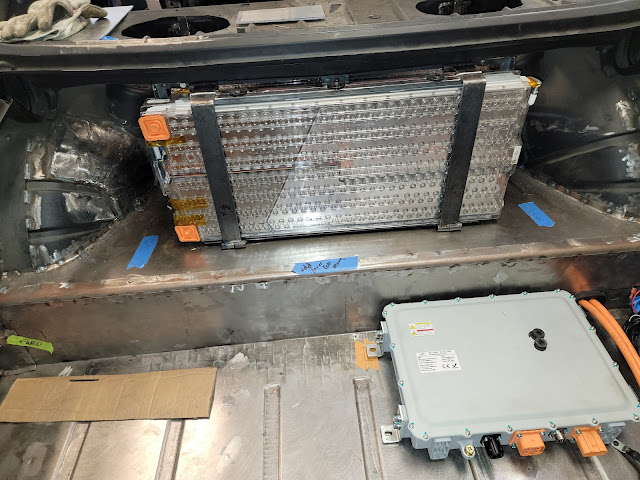

The location for the 4 Tesla batteries in the trunk area, under the

package tray

|

Enter the trunk area. After cutting away all the original metal to

fabricate mounts for the Tesla drive unit, I built a custom trunk floor.

I still want a usable trunk but there is a lot that needs to go back there:

- 4 Tesla battery modules

- Onboard charger

- DC/DC converter

- Drive unit controller

- High voltage traction contactors

- Pyro fuse

- J1772 charge plug

- Contactors for AC and heater

- Cooling lines for batteries and OBC/DC-DC

- Fuse box

- Pre-charge controller

- 12v startup battery

- Battery lover

- Stereo amplifier

Ideally, the batteries would fit under the package tray behind the rear seats

but there is only enough height for 3. Originally, I thought the last

battery would be located on the trunk floor with the rest of the electronics

but Brett came up with a brilliant idea to put it vertically in front of the

other three. This sticks out a bit further than the trunk opening line

but is still way better. It keeps all the batteries, with their cooling

lines and wiring, all together, keeps the weight closer to the middle of the

car, and leaves tons of space for other components.

Brett fabricated a super cool "briefcase" rack that hinges to secure that last

battery.

|

|

Controlling the heat near the battery with TIG

|

|

|

Fabricating the fold down briefcase rack

|

|

| Custom hinges |

|

|

Test fit with two real batteries and two mock foam batteries

|

I made my first four holes in the trunk, one for the Tesla traction HV cables

to the drive unit, one for the BMS cell tap and thermistor harness to the

batteries, and two for the coolant ports on the OBC. I attached nipples

to the OBC to extend the ports and ran them outside the trunk so that the

hoses are under the car, outside the trunk area.

|

|

Beginning layout of electrical components in trunk (contactor box, pyro

fuse, combo OBC/DC-DC)

|

|

|

HV cables run from trunk to Tesla drive unit

|

|

|

OBC cooling nipples extended to run outside trunk

|

|

| Laying out cabling |

|

|

Factory Tesla grommet for HV cables

|

|

|

Tesla HV harness for traction with pyro fuse in case of accident/short

|

|

|

4th rear battery all buttoned up in its suitcase

|

|

|

Rear batteries all wired up

|

|

|

Getting the trunk wiring almost finished...

|

|

|

HV cabling underneath from front battery box and to A/C compressor and

heater

|